production demands are evolving swiftly, demanding precision and performance to remain competitive. a single vital space driving modernization is the use of customized fixtures and jigs in manufacturing procedures. These critical equipment ensure the accuracy and efficiency of manufacturing lines, specially when tailor-made to specific industry requires. By integrating tailor made options, businesses can satisfy exceptional manufacturing challenges when obtaining better high-quality and maximizing output. This website click here explores how customization in fixtures and jigs is reshaping production and highlights its benefits for precision industries.

Table of contents:

Tailoring Fixtures to precise generation Requirements

the whole process of developing Custom Jigs for specialised duties

great things about Collaborating with producers for custom-made answers

serious-environment Examples of custom made Fixtures maximizing productiveness

Tailoring Fixtures to precise creation Requirements

Fixtures are integral to ensuring that elements continue to be mounted and appropriately aligned through the production course of action. tailor-made fixtures are produced with precise manufacturing needs in mind, adapting to one of a kind solution Proportions, workpiece balance requirements, and operational demands. one example is, makers during the automotive or aerospace sectors count on remarkably specialised fixtures to control complicated assembly processes when maintaining tolerances inside of microns. These customizations ensure that Every creation step is repeatable and accurate, doing away with errors that may compromise high quality or safety. With precision mechanical sections turning out to be the benchmark for prime-carrying out industries, personalized fixtures serve as the spine in their operations.

The Process of building personalized Jigs for specialised jobs

tailor made jigs are invaluable when output traces require dependable precision and efficiency. the procedure commences with understanding the manufacturing necessities and operational worries confronted by a business. By conducting a detailed style consultation, brands can make jigs that simplify complicated manufacturing steps whilst cutting down cycle periods. whether or not for drilling, slicing, or assembly, personalized jigs deliver regularity to high-volume manufacturing environments. They're usually fabricated making use of durable elements like steel or aluminum, capable of withstanding extended output operates without compromising overall performance. Sophisticated production technologies for example CAD software program or 3D modeling further streamline the design approach, making certain the jig integrates seamlessly into current workflows. The result? really efficient manufacturing lines that execute duties with unparalleled accuracy.

advantages of Collaborating with companies for personalized methods

selecting to personalize fixtures and jigs unlocks a range of benefits for makers planning to stay aggressive. First of all, customization maximizes operational effectiveness, as customized remedies align flawlessly with the necessities with the production line. Secondly, collaboration with knowledgeable manufacturers assures specific materials assortment and style, translating to sturdy factors that happen to be created to past. Lastly, personalized alternatives permit for a lot quicker generation cycles and minimized downtime, as machines and tooling are optimized for smooth operations. participating responsible partners like Shenzhen Yongxinglong Industrial progress Co. for tailor-made jigs and fixtures assures substantial products high-quality by way of pro craftsmanship and Innovative output approaches. By Doing the job closely with these specialists, businesses also acquire entry to cutting-edge innovations that improve long-phrase effectiveness.

genuine-World Examples of customized Fixtures boosting Productivity

Practical applications of personalized fixtures and jigs display their critical purpose in modern day manufacturing units. For example, Shenzhen Yongxinglong collaborates carefully with automotive and electronics companies to build specialized welding fixtures. These fixtures guarantee seamless alignment of car areas through automatic welding functions, resulting in more powerful bonds and minimized assembly glitches. equally, tailor made jigs for electronics manufacturing revolutionize precision assembly, enabling flawless placement of micro-elements. These enhancements aid enterprises meet stringent market benchmarks by attaining dependable precision. By incorporating custom made models, industries for instance aeronautics and major equipment can easily minimize cycle periods significantly, improving the two efficiency and profitability.

Customization in fixtures and jigs manufacturing is A vital financial commitment for industries in search of excellence. personalized answers from experienced companies like Shenzhen Yongxinglong Industrial improvement Co. unlock unparalleled precision and effectiveness, ensuring companies can fulfill their manufacturing ambitions even though preserving a aggressive edge. From decreasing cycle moments to enhancing solution top quality, the main advantages of tailored fixtures and jigs are plain. are you presently able to elevate the efficiency within your producing line? Make contact with Shenzhen Yongxinglong To find out more about how their large-high quality jigs and fixtures can fulfill your specific demands.

Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Kelly McGillis Then & Now!

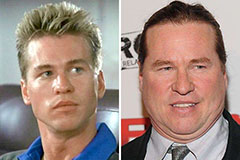

Kelly McGillis Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now!